Already a subscriber? Activate your premium account

Potatoworld Magazine

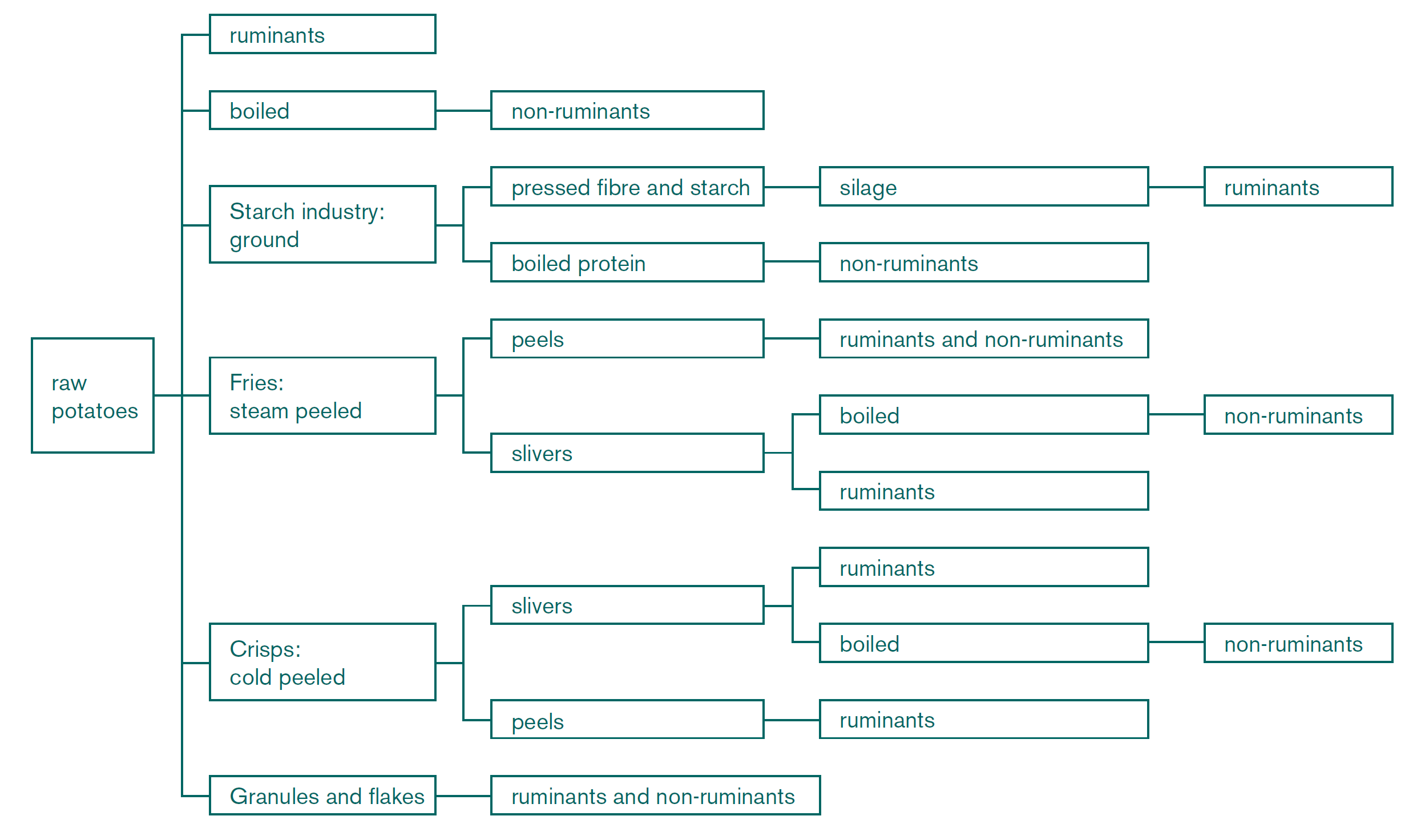

As mentioned in this blog, potato can be used as animal feed. The processing industry for food products collects potatoes from farms. The tubers are then sorted and graded according to specifications that vary for various products such as chilled fresh and frozen products. After washing, they receive a steam treatment whereafter the loose skin is brushed off. The industrial waste (comprising steam peels, slivers, pre-fried products, starch flakes and crisps) is used as animal feed.

The steamed peels are removed with brushes with varying degree of rigidity, thus also releasing the underlying starch and leaving three types of peels: high, moderate and low in starch. The product is a liquid which, due to fermentation, reaches a low pH and can be stored for a long time in silos. It is fed to cattle as well as pigs, steaming after all is cooking. Potato scrapings result from cold peeling of potato as is done for crisping potatoes. This product is not fit for pigs since the starch is not unlocked by heating, so it can only be fed to ruminants. The same holds true for potato slivers, small pieces of peeled potatoes that after cutting are not useable for the finished product. This waste product is very palatable for cattle as well as goats and sheep as it is tasty and rich in energy. It can be ensilaged and kept for up to one year.

There are two types of animal feed that are very suitable to feed pigs. These products have been heated making them accessible for enzymatic digestion. The first type becomes available in crisps factories. At the start or at completion of a cycle of crisp production, the crisps are unsuitable for sales purposes as not all processes are fine tuned. Next in crisps making, there are also many rejected crisps that are sorted. The rejected crisps material is ground and can be stored for a long time because of its low dry water content below 10 percent. The second type becomes available in chips factories. Like crisps makers, chips makers have rejected material available as pig feed, which, due to its water content of over 40 percent needs to be ensilaged when fermentation leads to a low pH, so it acidifies. It is ready to be fed after five weeks and can be stored for many months.

When cutting potato for the production of crisps and chips, the water in which this takes place contains starch. Starch being heavier than water is removed through centrifuging and decanting. Crisps factories that peel the potatoes cold produce a firm product containing 50 percent water that can be piled. Due to their application of steam peeling, factories making French fries produce a liquid product containing 75 percent water. The product is fermented to reach a low pH and can be pumped for silage purposes. Such a potato product is only usable for ruminants. If heated, the liquid starch substance can also be fed to pigs and its feed value improves when mixed with the steamed peels.

Potato granules and flakes when water or milk is added make reconstituted mashed potato. When producing potato granules (small potato parts are blanched, heated briefly and dried) and potato flakes (peeled potato is cut, well boiled, ground and dried in a drum dryer and ground again), waste products are formed when starting up lines and closing them and when rejecting an unsuitable product. Potato flakes are also produced by some factories from the slivers. The rejected material leaves the factory as feed for cattle as well as pigs.

Events

©2015 - 2024 Potatoworld | Webdesign and realisation COMMPRO