Already a subscriber? Activate your premium account

Potatoworld Magazine

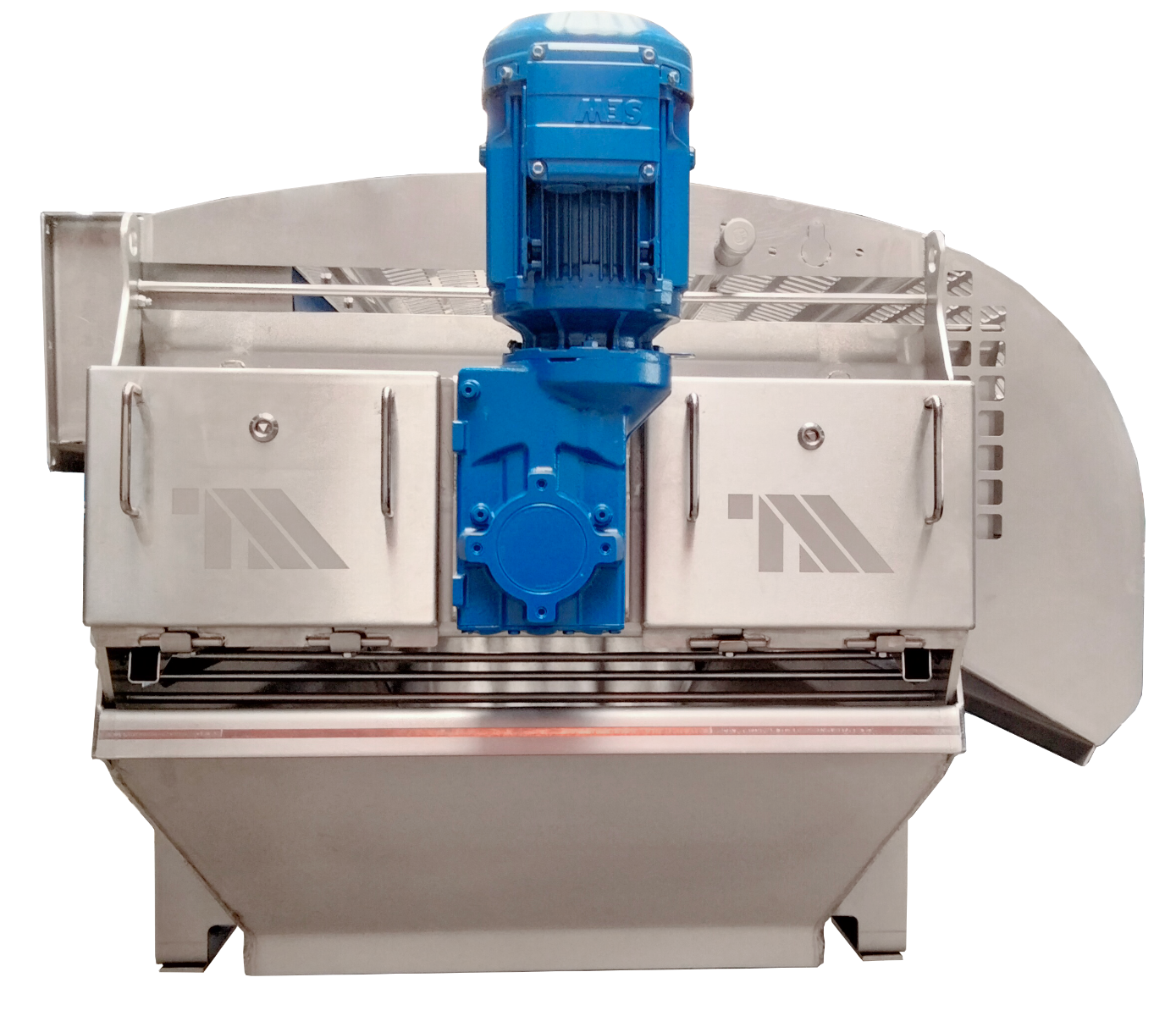

Tummers Food Processing Solutions recently introduced a new spreading machine: the Delta Roller Spreader.

According to the machine building company, taking a closer look at the sorting processes resulted in an improved spreading machine that improves efficiency. The specially shaped rollers of the new Delta Roller Spreader ensure a higher return and extended maintenance intervals.

The new spreading machine is part of the company’s peeling process. After steam peeling, brushing and washing, this machine spreads the product for an optical sorter that detects foreign objects and abnormalities. Objects that are too small fall through the gaps between the rollers and are taken out of the process. The machine is commonly used to transport potatoes from a screw transportation system to an optical sorter, but is suitable for a variety of food products.

As previous spreading methods with hexagonally shaped rollers showed bouncing movements, the company decided they could do better. ‘We eventually discovered that triangular rollers with a radius on the flat sides reduce the bouncing. This prevents the product from damaging and improves the supply to the optical sorting machine, reaching higher returns as a result’, explains Business Development & Sales Manager Edwin Langbroek.

When fine-tuned perfectly, the triangular shaped rollers ensure a constant gap in any position. According to Langbroek, this brings great advantages: ‘A constant gap prevents foreign objects like rocks and other contaminations from jamming, so the machine can keep running constantly with a reduced chance of damage. As a result, the Delta Roller Spreader has an extended lifetime with extended maintenance intervals!’

Tummers announces that, apart from the mentioned advantages, with the Delta Roller Spreader the company also aims for affordability. Instead of ten rollers featured in the company’s previous spreading machine, seven rollers are now sufficient. ‘The machine therefore consists of fewer parts than the previous model and due to a special production method for the rollers, this machine can also compete very well price-wise’, the BD & Sales Manager states.

Events

©2015 - 2024 Potatoworld | Webdesign and realisation COMMPRO