Already a subscriber? Activate your premium account

Potatoworld Magazine

In rapid multiplication schemes, plants are multiplied by in vitro or in vivo (not in closed tubes or containers) techniques. Cuttings are rooted to allow them to develop into fully grown plants that make tubers, flowers and seeds. Rapid multiplication starts by allowing a tuber to sprout. The top of the sprouts of a few cm in length are used to produce new plantlets.

Next, there is the excision of a tip of the meristem, called an explant (plant part cut from a plant), which has the size of around 100 μm (one 10th of a millimeter). It consists of the apical dome and a few leaf primordia. The apical meristem is a group of rapidly dividing cells where no viruses, bacteria, mycoplasms and fungi are present, not even in infected plants. Once the apex of the sprout of the potato stops to divide, viruses start to move into the tissue. The tip is cultured on a Murashige and Skoog (MS) medium containing growth regulators under sterile conditions in a test tube. The larger the explant, the higher the recovery rate, but larger explants also have a higher risk of virus contamination, so there is a balance.

Rapidly developing a large population of plantlets

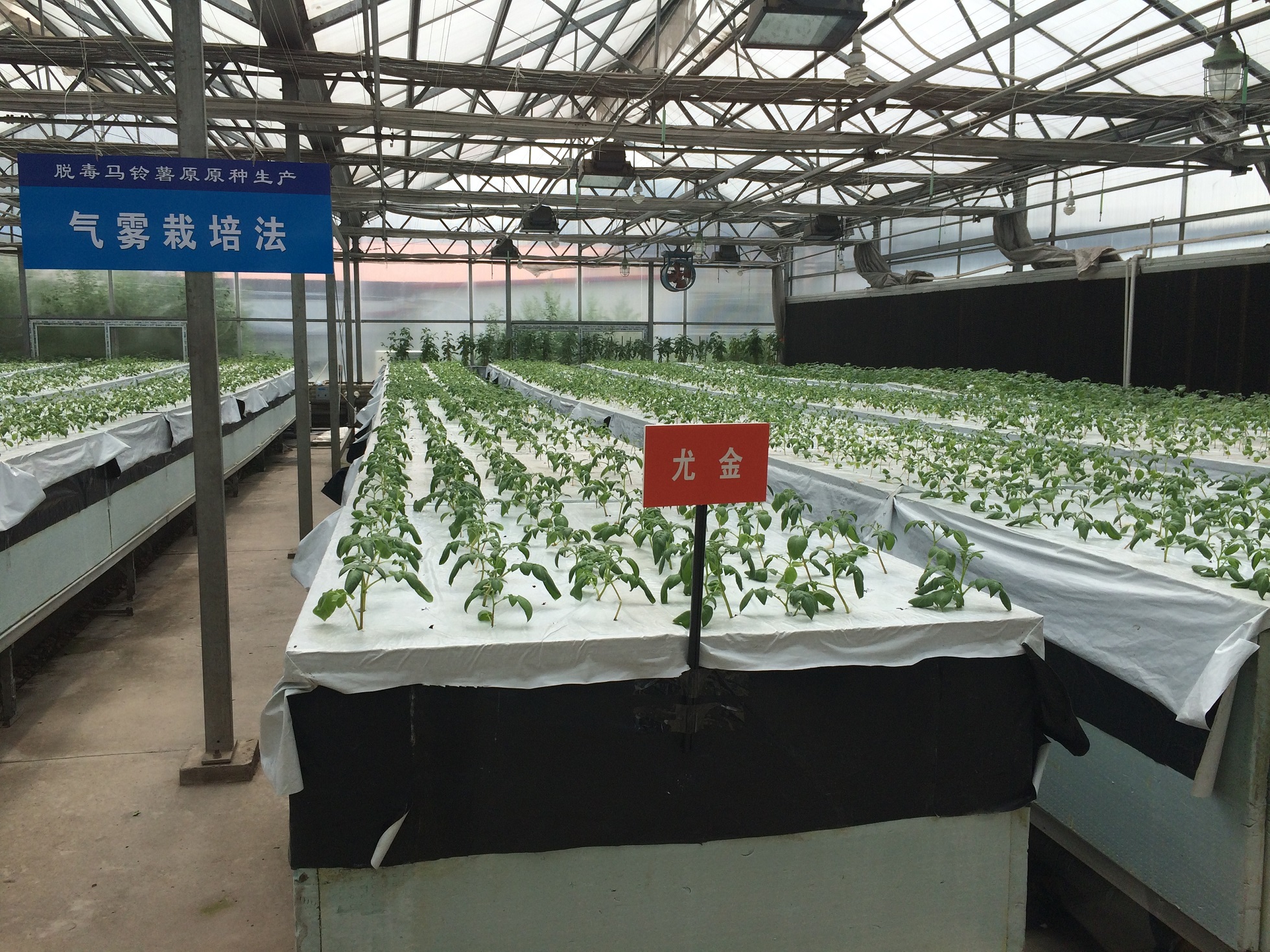

The explant forms a tissue, a callus, which due to gravitation forms roots at the base and a shoot at the top end. By cutting the in vitro plantlet below each node and rooting each piece in the MS medium, a large population of plantlets is rapidly developed. In order to grow mini-tubers from them, the rooted plantlets are transplanted into sterile soil, peat, or other media supplied with water and minerals (aeroponics with roots hanging in moisturized air and hydroponics with roots hanging in water) and are allowed to form fully grown plants. Mini-tubers are grown in media soil, water or air in a greenhouse or screenhouse. If, however, the in vitro plantlets are subjected to short daylengths of around 12 hours, they initiate tubers (micro-tubers) in the leaf axils, which can also be used as basic seed tuber material in a seed potato production scheme. At the industrial level, this method has been perfected by applying a temporary immersion technique (TIS) assisted by illumination, additional carbon dioxide, sucrose and growth-promoting substances.

Image: Micro-tubers produced in vitro and mini-tubers in a greenhouse are virus-free materials.

Events

©2015 - 2024 Potatoworld | Webdesign and realisation COMMPRO